SD220L Crawlerpompo e felletseng ea haeterolikimochini oa ho cheka o potolohang ka moraoe sebelisoa haholo bakeng sa ho cheka ho otlolohametheo ea liqubuka bophara bo boholo, majoe a manyenyane, lefika le thata le mekhahlelo e meng e rarahaneng. Bophara ba eona bo boholo ke 2.5m (lefika), botebo ba ho tjheka ke 120 m, 'me matla a maholo a majoe a nang le masoba a ka fihla ho 120MPa, e sebelisoang haholo kahong ea ho tjheka ea metheo ea liqubu likoung, likoung tsa likepe, marokhong a linoka, matšeng le maoatleng ka melemo ea ho tsamaea ka potlako le boiketsetso bo phahameng, 'me e boloka litšenyehelo tsa basebetsi le tsa kaho.

Mofuta oa ho Hlakola o Tlase

Sebopeho sa mantlha le litšobotsi tsa ts'ebetso

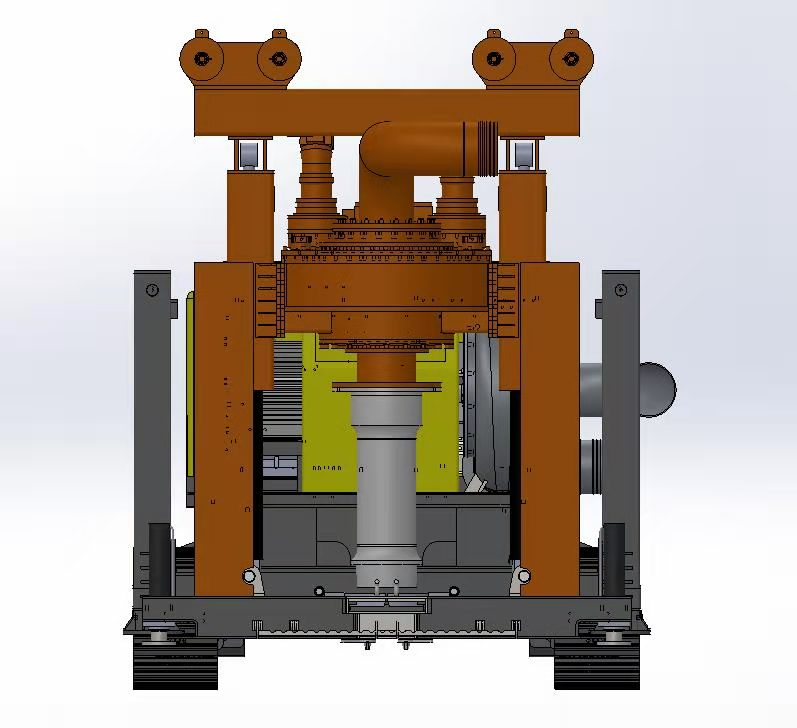

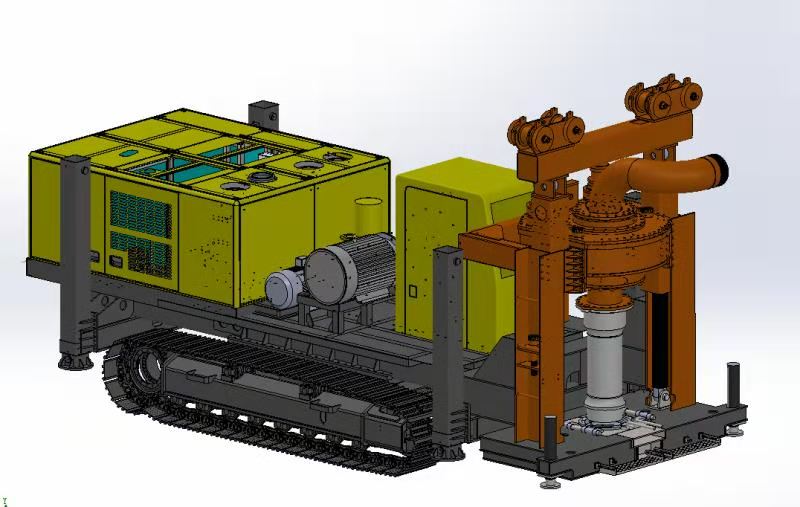

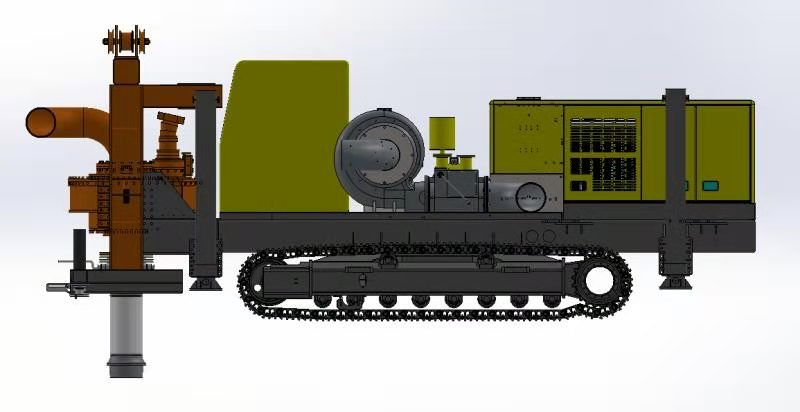

- Sebopeho se seholo

- Thepa e amohela chassis ea ho crawler, sistimi ea hydraulic e entsoeng ka enjene

'Me pompo ea haeteroliki e kentsoeng ka morao ho koloi e etselitsoe ho khanna sesebelisoa sa ho fokotsa motlakase se khannang tšisi ea ho hahaba, e etsang hore e sebetse ka bo eona.

2. Li-jack tse 'ne tsa hydraulic li kentsoe mahlakoreng a ka pele le a ka morao a chassis ea tsela. Mochini o ka sehloohong o ka tšehetsoa 'me maemo a ka pele, a ka morao, a leqele le a le letona a ka fetoloa ntle le ho leka-lekanya mobu oa sebaka sa kaho. Li-jack li ka buloa le ho koaloa ka bolokolohi tlas'a taolo e arohaneng. Nakong ea kaho, li-jack tsa hydraulic lia atolosoa, 'me bophara bo boholo ba fulcrum ea li-outrigger tse ka letsohong le letšehali le le letona bo ka fihla ho 3.8m.

3. Karolo ea ho phunya ea rig e tsitsitsoe karolong e ka pele ea sethala sa chassis 'me e behiloe ka holimo (boemo ba ho sebetsa).

4. Foreimi ea gantry le foreimi ea ho bula lemati karolong e ka tlase ke sebopeho se kopaneng, se ntlafatsang botsitso ba sebopeho ka kakaretso sa foreimi haholo.

5. Foreimi e nyenyane ea gantry e kentsoe ka hare ho gantry, e leng se sa eketseng feela ts'ebetso e tataisang, empa hape se etsang hore kaho e be e tsitsitseng haholoanyane, 'me e lelefatsa bophelo ba ts'ebeletso ea phaephe ea ho phunya haholo. Hlooho ea motlakase e kentsoe ka hare ho pheletso e ka tlase ea foreimi e nyenyane ea gantry. Silindara ea hydraulic e sebelisetsoang ho phahamisa hlooho ea motlakase (ho kenyeletsoa le foreimi e nyane) e kentsoe ka har'a tube ea sekwere ea mullion ea foreimi e nyenyane.

6. Hlooho e potolohang e sebelisa hlooho e potolohang ea rig ea ho cheka e potolohang, e eketsang torque ea tlhahiso

e khannoang ke lienjene tse tharo tse feto-fetohang tsa 107

7. Molune o nepahetseng oa gantry o na le sesebelisoa sa ho laola le crane ea cantilever (e entsoeng ka winch ea hydraulic, cantilever, pulley, jj.). E sebelisetsoa ho qhaqha le ho kopanya liphaephe tsa ho phunya.

8. Haufi le ka morao ho gantry, karolo e bohareng le e ka pele ea sethala e na le tekesi, e nang le sesebelisoa sa ts'ebetso, skrine ea ponts'o, sehatsetsi sa moea, jj.

9. Ka mora tekesi le bohareng ba sethala, ho kentswe pompo ya lerōle. Pompo ya lerōle e kgannwa ka ho toba ke enjene ya 90kw. Tahlehelo ya matla ya phetoho ya motlakase le ya haeteroliki e qojwa. Ka nako e ts'oanang, ditjeo tsa kaho di a fokotseha.

10. Seteisheneng sa pompo ea hydraulic ka morao ho sethala, ho kentsoe litsamaiso tse peli tse ikemetseng tsa hydraulic:

10.1 Sistimi ea haeteroliki ea maeto e entsoe ka enjene ea diesel ea Cummins ea 197kw le pompo ea matla a feto-fetohang a phallo e sa fetoheng, e sebelisetsoang enjene ea maeto, silindara ea outrigger ea enjene e kholo, silindara ea outrigger ea foreimi e bulang monyako, silindara ea ho phahamisa le likarolo tse ling tse tsamaisang. Ho bonolo ho tsamaea sebakeng sa kaho le ho lokisa masoba a liqubu tsa rig ea ho cheka.

10.2 Sistimi ea haeteroliki ea hlooho e potolohang e entsoe ka pompo ea motlakase e sa fetoheng ea 132kw ea mekhahlelo e meraro le pompo ea motlakase e sa fetoheng ea phallo e mpe, e sebelisetsoang mosebetsi oa hlooho e potolohang, silindara ea oli e phahamisang, silindara ea oli e laolang, winch ea hydraulic le likarolo tse ling tse tsamaisang matla.

Sistimi e tsoetseng pele ea hydraulic e etselitsoe ka ho khetheha ho tsamaisa pompo ka morao ho monya. Pompo e kholo, enjene ea hlooho e potolohang, valve e kholo, valve e thusang e utloang mojaro le likarolo tse ling tsa hydraulic li entsoe ka Rexroth, Kawasaki ea Korea, hydraulic HC ea Italy, Jiangsu Hengli, Sichuan Changjiang Hydraulic le lihlahisoa tse ling tse tsebahalang lapeng le kantle ho naha, ka ts'ebetso e phahameng le e tsitsitseng.

11. Likarolo tsohle tsa bohlokoa (ponts'o le molaoli) oa sistimi ea taolo ea motlakase ke likarolo tse tsoang linaheng tse ling tsa lihlahisoa tse tummeng tsa machaba le liphutheloana tsa mantlha tsa boleng bo holimo; Lebokose la taolo le amohela likarolo tse tšepahalang tsa ho thella ha lifofane le ho li polaka; Theha sistimi e khethehileng ea taolo ea motlakase bakeng sa ho hula pompo ea lapengmochini oa ho cheka o potolohang ka morao.

12. Switchboard e kentswe ka mora diteishene tse pedi tsa pompo ya hydraulic mme e kwahetswe ka dikoahelo hammoho le diteishene tse pedi tsa pompo ya hydraulic.

13. Ha pompo ea seretse e beoa sethaleng, sebaka se pakeng tsa pompo ea seretse le metsi a holim'a lesoba la qubu sea fokotseha, ho phahamisa ha pompo ea seretse hoa khutsufatsoa, 'me ts'ebetso ea ho sebetsa ea pompo ea seretse e ntlafala haholo.

14. Tlhaloso ea moralo oa phaephe ea ho phunya:¢325x25x2000 Phaephe ea ho tjhesa e amohela khokahano e nang le khoele, e leng se loketseng ho kenngoa le ho qhaqhoa ka boiketsetso. Hlooho ea sehokelo le nate lipheletsong ka bobeli tsa phaephe ea ho tjhesa ke sehokelo se sekhutlo se sekhutšoanyane se tenya, se entsoeng ka 35CrMo, se timmeng le se hatselitsoeng, 'me phaephe ea ho tjhesa e entsoe ka 16Mn. Ts'ebetso ea ho tjhesa e amohela ho futhumatsa pele ho ho tjhesa le ho boloka mocheso kamora ho tjhesa. Boleng ba ho tjhesa ba phaephe ea ho tjhesa boa netefatsoa 'me bophelo ba ts'ebeletso boa ntlafala.

15. Lisebelisoa tsa ho tjheka: lisebelisoa tsa ho tjheka tse sebediswang disebedisweng tsena ke disebediswa tsa ho tjheka tse potolohang. Disebediswa tse fapaneng tsa ho tjheka di kgothalletswa basebedisi ho ya ka maemo a fapaneng a jeoloji. Ho ya ka sebopeho, ho na le disebediswa tsa ho tjheka tse potolohang tsa mapheo a mabedi, mapheo a mararo le a mane; Sesebediswa sa ho tjheka se potolohang sa cylindrical. Tlhophiso ka meno a ho tjheka: ho na le meno a ho tjheka a mofuta wa scraper, meno a ho tjheka a roller le meno a ho tjheka a sehang.

- Litšobotsi tsa ts'ebetso

1. Pompo ea lerōle e entsoeng ke litsebi tsa tlhokomelo ea metsi tse tsoang Univesithing ea theknoloji ea Jiangsu ke eona e tsoetseng pele ka ho fetisisa Chaena. Impeller e na le bokhoni bo phahameng ba ho sebetsa, 'me impeller ea kanale e habeli e amoheloa, ka phello e tsotehang ea ho boloka matla. Sekoti sa pompo le impeller li entsoe ka tšepe e ngata ea chromium le ts'ebetso ea ho lahla matsete, ka qetello e phahameng ea bokaholimo, khanyetso e ntle ea ho tsofala le bophelo bo bolelele ba ts'ebeletso. Impeller e amohela teko ea ho leka-lekana e matla, ka botsitso bo phahameng le lebelo le potlakileng. Hafeela chelete ea impeller e le likaroloana tse tiileng tse nyane ho feta bophara ba ka hare ba phaephe ea ho phunya, ho kenyeletsoa le li-block tsa majoe le majoe a maholo, e ka ntšoa, e qobang ho silakanngoa khafetsa ha likaroloana tse tiileng le majoe a maholo. Bokhoni bo phahameng ba ho tlosa slag.

2. Matla a maholo a ho phahamisa le ho phahamisa, haholo-holo a loketseng jioloji e rarahaneng joalo ka lehlohlojane, majwe a manyenyane le lefika;

3. sesebelisoa sa ho laola le sa ho thusa se hlophisitsoe foreiming ea gantry, e leng se loketseng, se tšepahalang le se bolokang basebetsi bakeng sa ho tlosa le ho kenya liphaephe tsa ho phunya;

4. Hlooho e potolohang: tlhahiso ea motlakase e sa fetoheng, phetiso e iketsang. Tlas'a maemo a fapaneng a jeoloji, enjene e feto-fetohang ea hlooho e potolohang e fetola torque ea tlhahiso le lebelo la tlhahiso ka bo eona, ka tekanyo e phahameng ea othomathike, lebelo le potlakileng la maoto le katleho e phahameng ea kaho.

5. Sesebelisoa le skrine sa pontsho ka har'a tekesi li bonts'a data ea ts'ebetso ea sistimi ka 'ngoe ka nako ea sebele, e le hore mokhanni a ka tseba boemo ba ts'ebetso neng kapa neng.

Tlhaloso

| Enjene | Mohlala |

| Cummins | |

| Matla a lekantsoeng | kw | 197 | ||

| Lebelo le lekantsoeng | r/motsotso | 2200 | ||

| Bophara ba Max.drill | mm | 2500()Lefika) | ||

| Botebo ba ho cheka ka ho fetisisa | m | 120 | ||

| Ho khanna ka rotary | Torque ea Max.output | KN·m | 220 | |

| Lebelo la ho potoloha | r/motsotso | 4-17 | ||

| Silindara ea ho phahamisa | Ho hula piston ka lebelo le phahameng ka ho fetisisa | KN | 450 | |

| Push ea piston e hulang ka lebelo le phahameng | KN | 37 | ||

| Seteishene sa piston se hulang tlase ka ho fetisisa | mm | 800 | ||

| Pompo ea lephaka | Matla a tšehetsang | KW | 15 | |

| Khatello e phahameng ka ho fetisisa | Pa | 3300 | ||

| Phallo e phahameng ka ho fetisisa | L/S | 138.3 | ||

| Pompo ea seretse | Matla a tšehetsang | KW | 90 | |

| phallo | m³/h | 1300 | ||

| Hlooho | m | 1200 | ||

| Seteishene se seholo sa ho pompa | Matla a tšehetsang | KW | 132 | |

| Khatello ea ho sebetsa ea sistimi ea haeteroliki | MPa | 31.5 | ||

| Kreine e nyane e thusang | Matla a maholo a ho hula | KN | 10 | |

| Bophara ba thapo ea terata | mm | 8 | ||

| Lebelo le phahameng la winch | m/motsotso | 17 | ||

| Chasisi | Lebelo le phahameng la ho tsamaea | Km/h | 1.6 | |

| Bophara ba chesisi | mm | 3000 | ||

| Bophara ba pina | mm | 600 | ||

| Bolelele ba sebaka sa terene | mm | 3284 | ||

| Tlhaloso ea phaephe ea ho phunya | mm | Φ325x22x1000 | ||

| Boima ba enjene e kholo | Kg | 31000 | ||

| Litekanyo | boemo ba mosebetsi()Bolelele ×bophara × bophahamo) | mm | 7300×4200×4850 | |

| Boemo ba lipalangoang()Bolelele × bophara × bophahamo) | mm | 7300×3000×3550 | ||

- Ts'ebetso ea projeke

Sediriswa sa ho tjheka sa ho pompa ka ho kgutlela morao sa ho pompa. Ka ho potoloha ha metsi, thepa ya ho seha ka hara lesoba la qubu (seliba) e tswela pele ho iswa ka hara lesoba la seretse le pela lesoba la qubu (seliba) hammoho le seretse. Ka hara lesoba la seretse, lehlabathe, lejwe le thepa e meng e nang le di-granular e dula tlase ho tanka, mme seretse se phalla ka hara lesoba la qubu (seliba) ka ho tswela pele. Eketsa boemo ba metsi ba lesoba la qubu. Morero o ikgethang wa tshebetso ke o latelang:

3.1. Sekoti sa qubu se tla kenngwa lesobeng la qubu. Sekoti sa qubu se entswe ka poleiti ya tshepe e kgolo ho feta 5mm, mme bophara ba yona e tla ba 100mm e kgolo ho feta bophara ba lesoba la qubu ya moralo (sediba). Bolelele ba sekoti sa qubu bo itshetlehile ka maemo a jeoloji. Moeli o ka tlase wa sekoti sa qubu o lokela ho patwa lera la mobu le sa feleng mme o fete lera la ho tlatsa.

3.2. Haeba sebaka se ka morao se tebile haholo 'me mosebetsi oa ho cheka kapa oa matsoho o sa sebetse, mosebelisi a ka etsa karolo ea ho phunya ka barele ka ho khetheha 'me a e lokise holim'a drile ho cheka masoba. Botebo hangata ha bo fete 10m. Joalokaha ho ka ba joalo. U se ke ua putlama.

3.3. Bokgoni ba ho epolla sekoti sa seretse bo tla ba boholo ho feta bophahamo ba lesoba la qubu. Ho molemo ho sebedisa sebopeho se kgutlonnetsepa, se ka eketsang nako le lebelo la ho kgutlela ha seretse sekoting sa qubu, mme thepa e nang le granular e ka dula ho fihlela moo e ka kgonang teng.

P1: Na u moetsi, k'hamphani ea khoebo kapa motho oa boraro?

A1: Re moetsi. Feme ea rona e Profinseng ea Hebei haufi le motse-moholo oa Beijing, lik'hilomithara tse 100 ho tloha koung ea Tianjin. Re boetse re na le k'hamphani ea rona ea khoebo.

P2: Kea ipotsa hore na o amohela diotara tse nyane?

A2: Se tšoenyehe. Ikutloe u lokolohile ho ikopanya le rona. E le ho fumana liodara tse ling le ho fa bareki ba rona boiketlo bo eketsehileng, re amohela liodara tse nyane.

P3: Na o ka romela dihlahiswa naheng ya heso?

A3: Ehlile, re ka khona. Haeba o se na sesebelisoa sa hau sa ho tsamaisa thepa ka sekepe, re ka o thusa.

P4: Na u ka nketsetsa OEM?

A4: Re amohela liodara tsohle tsa OEM, ikopanye le rona feela 'me u mphe moralo oa hau. Re tla u fa theko e utloahalang 'me re u etsetse lisampole kapele kamoo ho ka khonehang.

P5: Melao ea hau ea tefo ke efe?

A5: Ka T/T, L/C HA HO BONWA, depositi ea 30% esale pele, tekanyo ea 70% pele ho romelloa.

P6: Nka etsa odara joang?

A6: Saena PI pele, lefa depositi, ebe re tla hlophisa tlhahiso. Kamora tlhahiso e felileng o hloka ho lefa tjhelete e setseng. Qetellong re tla romela thepa.

P7: Nka fumana khotheishene neng?

A7: Hangata re o qotsa nakong ya dihora tse 24 kamora hore re fumane potso ya hao. Haeba o potlakile haholo ho fumana khotheishene, ka kopo re letsetse kapa o re bolelle ka poso ya hao, e le hore re ka nka potso ya hao e le ya bohlokwa.

P8: Na theko ea hau ea tlholisano?

A8: Re fana ka sehlahisoa sa boleng bo botle feela. Ka sebele re tla u fa theko e ntle ka ho fetisisa ea fektheri ho latela sehlahisoa le tšebeletso e ntle.